FIBAR DISTRIBUTORS INC.

Delivering an innovative solution to steel rebar

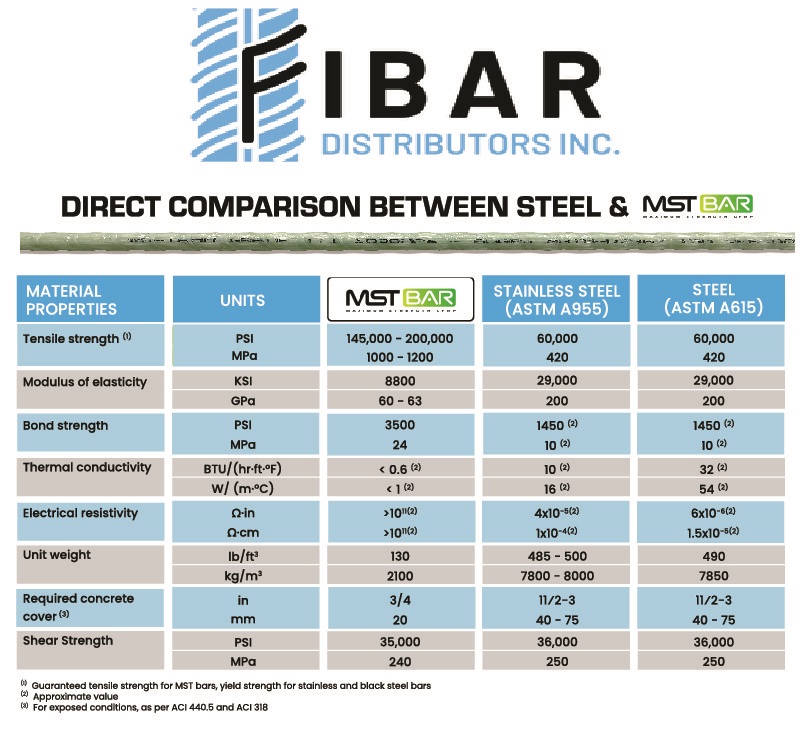

Fibar Distributors Inc. proudly distributes MST-BAR; a Glass Fiber Reinforced Polymer (GFRP) Rebar, the future of concrete reinforcing.

Fiberglass rebar is an incredibly innovative product and we are proud to distribute MST Rebar Inc. Canadian-made products that will save your business money on labour, shipping and handling costs and improve the durability and longevity of your projects.

WHY FIBERGLASS REBAR?

Steel rebar was developed as the only option for reinforcing concrete. Structures using steel rebar in corrosive environments will begin to fail immediately due to the corrosion aspect of the product. Corrosion costs the private and public sectors hundreds of billions of dollars in repair and maintenance costs a year. Corroding steel rebar is a ticking time bomb because determining the moment of failure can mean the difference between life and death.

MST-BAR is suitable for use wherever concrete needs to be reinforced. Whether it is structural, non-structural or custom products, MST-BAR can provide the rebar to meet your needs. Because of the non-corrosive nature of fiberglass rebar, MST-BAR is especially important to use in coastal areas to avoid degradation and save on costly repairs.